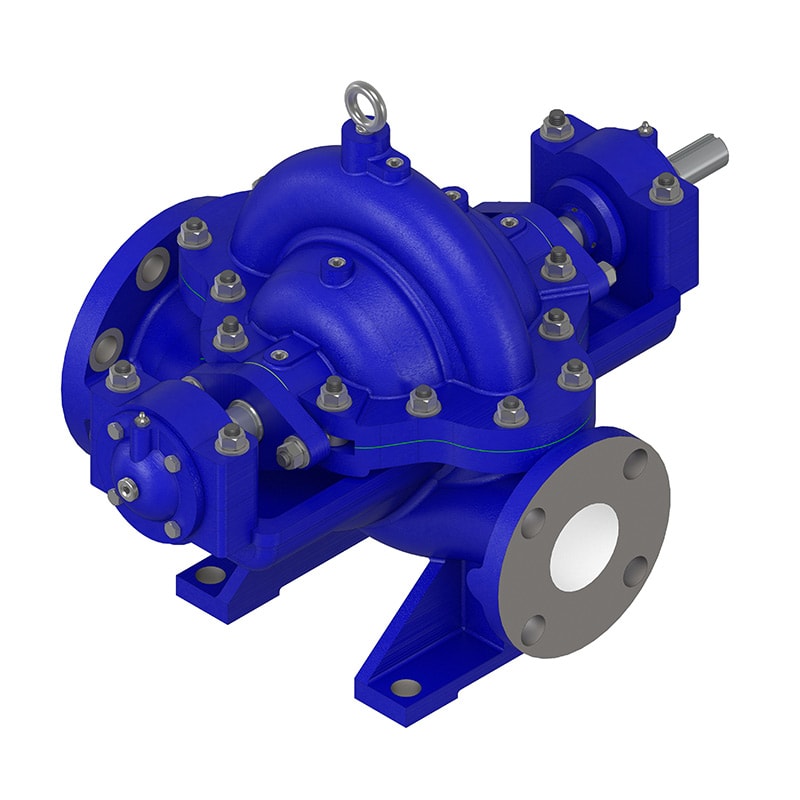

Working in partnership with a municipal wastewater treatment client, Smart Turner Pumps Inc designed and manufactured two the above double suction pumps for use in a pressure screen wash application. Using our in house milling, boring, and turning capabilities, the bodies of the pumps were built to our customer's specifications. Upon quality controlled construction and assembly, hydrostatic testing, and final engineering approval, direct delivery to the end user and on-site commissioning was coordinated.

In addition to the units as finished products, Smart Turner Pumps provided training to local wastewater personnel on the operation and maintenance of such to further explain and note their features, including discharges, gauges, bearings, and motors. With consistent performance in pumping water to, and through, municipal pumping stations, our follow up customer relations have indicated their high degree of satisfaction with our exemplary production and assistive cooperation throughout the course of this project.

Project Details of Two Double Suction Pumps

| Product Description | These 2 Double Suction Pumps are used within a wastewater treatment application. Used as pressure screen wash pumps. |

| Capabilities Applied/Processes | Line Boring on Horzontal boring mill, Milling machine, Lathe Hydrotestic testing is standard on all pumps. 175 psi / 10 minutes On-Site Commissioning Start-Up Supervision Training

|

| Overall Pump Dimensions | Length: 64.57" Width: 34.0" Height: 24.13" Suction Inlet: Ø6" Discharge Outlet: Ø4" |

| Tightest Tolerances | ±0.0005 |

| Material Used | Impeller: ASTM A-48 Class 30 Cast Iron Shaft, Motor Housing, Seal Plate: 416 Stainless Steel |

| Finishing | Primed & Painted |

| Features | Pressure Gauges

Motor Specifications:

|

| Pump Flow Data | Fluid: Water

|

| Industry for Use | Wastewater Treatment |

| Delivery Location | Hamilton , Ontario |

| Standards Met | Customer supplied specifications |

| Product Name | Manufacturing & Commission of 4FG Double Suction Pumps |